Tools

Freehand Routing / Engraving / CNC

My wife, Rev. Dr. Rhonda Schienle, provides custom and themed wedding services. There is a beautiful poem titled "The Marriage Box", that she has incorporated into her services, which includes a box. She asked me to design and build classic boxes with heirloom features that could be provided as a memento for her couples. We use beautiful American hardwoods and brass hardware, along with precision sliding dovetail joinery for boxes that can keep your favorite items protected for a lifetime.

As part of the boxes, we typically include names, dates and a 3D engraving with a rotary tool called a palm router, which is in between a tiny Dremel and a full-size router. In early 2019, we began designing and routing these with a CNC router to provide precise lettering and depth of artwork which is not achievable by hand at an acceptable price-point. You can see several examples of these boxes on our Weddings and Boxes pages. The CNC and palm routers are shown below. The palm routers are used for easing (rounding over or chamfering) the edges of boxes, as well as minor touch up or simple additions that are not appropriate for the CNC.

Joinery

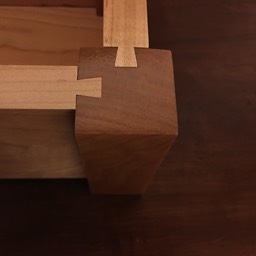

The majority of our boxes are constructed using a post and panel model with sliding dovetail joints. The vertical posts are thicker than the panels, and the panels are connected to the posts using a sliding dovetail.

A dovetail is a locking joint with tremendous strength compared to many other wood joints. The canted walls give the sliding dovetail joint a decided strength advantage over a dado, rabbit or butt joint. The joint mechanically resists tension, meaning that the tailboard can’t pull away from the grooved board. The wood must crush or break before the two parts separate. While it is not a complicated joint to make, it does require some finesse and patience, and the reward of the strength and appearance make up for the effort.

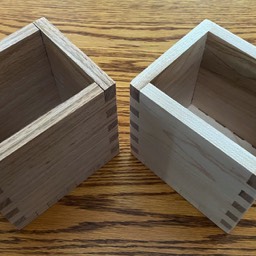

We also use box joints, which rely on the surface area of the glue to make a strong joint. Box joints look like exactly what the name implies, a square joint, where the amount of glue used ensures the joint is stronger than the wood itself.

Hardware

The barrel hinges used for securing the top to the base are made of solid brass with brass links. The base of the box has enough mass to allow the hinges to open 180 degrees without tipping over. The barrel hinges are invisible while the lid is closed. The barrel hinges are sunk into the base and top at the precise depth and distance to function correctly. A set screw is used in each barrel to expand them within their holes to stay in place.

Lathe

This is Penn State Industries' Turncrafter Commander 12" Variable Speed Midi Lathe. The Carbide tools pictured with it are BlackLine Turning Tools Midi set. The set includes a stainless steel handle and four carbide inserts (left to right): square, diamond, round and W. The inserts are mounted on shafts, which are inserted in the handle.

Lathes are used for turning objects from pens to table legs, or on a larger scale, missile bodies. I worked at Honeywell's Marine Systems Division in the 1980's and loved watching the mechanics operate the huge CNC lathes turning aluminum and steel billets into cylinders. These days, my usage is on a much smaller scale, typically a few inches at a time.

Turning a piece of wood from a small blank into a crafted pen is a very rewarding experience and involves several steps before it is mounted on the lathe. Once on the lathe, the pen is shaped with a few different tools, some to provide the rough shape quickly, others to provide internal and external curves, and others to etch fine lines into the material. The combination of these provides a custom pen or pencil every time.

Planer

This is a Wen 13-Inch, 3-Blade, Benchtop Thickness Planer. The 15 Amp motor provides over 25,500 cuts per minute, which can plane boards up to 13 in. wide and 6 in. thick with ease.

Thickness planers are used to plane, or smooth, rough and worn wood to give it an exceptionally nice finish. For shop stands, as shown, the finish is nice enough to use directly off the planer. There is no need for additional sanding for this type of work. It is excellent for smoothing out the transition between glued surfaces like large signs or plaques.

Planers are very proficient at generating large piles of sawdust and fine chips. Planing the boards shown in the stand built for this planer generated about 10 gallons of sawdust. I use a 5 gallon pre-stage cyclone attached to a 12-gallon Shop-Vac and was planing multiple 4 x 4's, 2 x 4's and 2 x 6's for several projects on the day I made the stand for this. In about 30 minutes I had to empty out the 5 gallon cyclone at least 6 times. Got mulch?